Quality Inspection

8+

Testing Processes

20+

Testing Equipments

99.5%+

Qualification Rate

20+

Quality Inspector

Fastener Quality Inspection

From raw materials to finished products, we implement rigorous quality inspections across all fastener types. Our advanced testing equipment ensures strength, durability, and reliability at every stage, guaranteeing products that meet the highest international standards.

Dimensional & Tolerance Testing

Dimensional Inspection

Ensures that every fastener meets precise size and tolerance requirements.

Go Gauge Testing

Confirms that fasteners fit correctly within the specified tolerance limits.

No-Go Gauge Testing

Verifies that fasteners do not exceed the maximum allowable dimensions.

Mechanical Performance Testing

Hardness Testing

Measures the material’s resistance to deformation to ensure durability and strength.

Torque Testing

Evaluates the fastening performance by testing the torque required for tightening.

Tensile Testing

Determines the fastener’s load-bearing capacity under tension and pressure.

Material & Metallurgical Testing

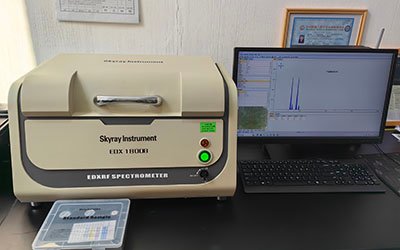

Spectrometer Analysis

Identifies and verifies material composition through precise spectrographic testing.

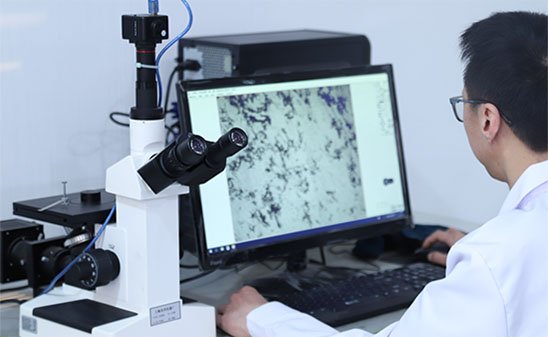

Metallographic Examination

Observes the microstructure of metals to assess quality and detect defects.

Surface & Environmental Testing

Coating Thickness

Ensures uniform plating or coating layers for protection and performance.

Salt Spray Testing

Simulates harsh environments to evaluate corrosion resistance of fasteners.

RoHS Testing

Ensures fasteners comply with regulations limiting hazardous substances.

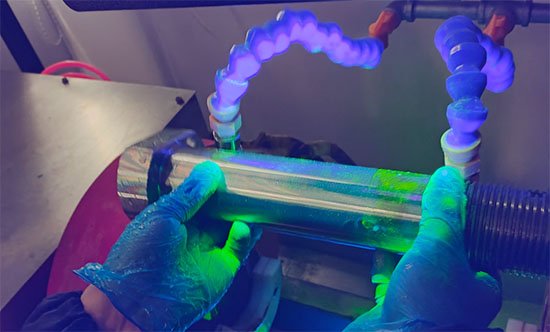

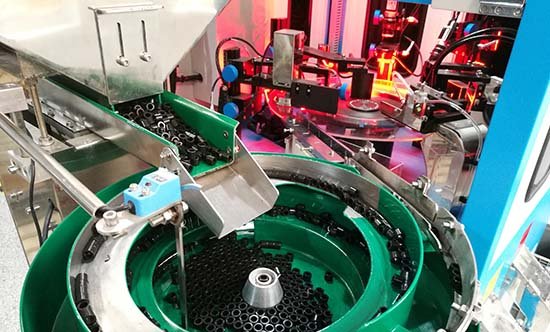

Non-Destructive & Automated Testing

Spectrometer Analysis

Detects surface and subsurface cracks or flaws in ferromagnetic materials.

Metallographic Examination

Uses automated vision systems to detect surface defects and dimensional variations.