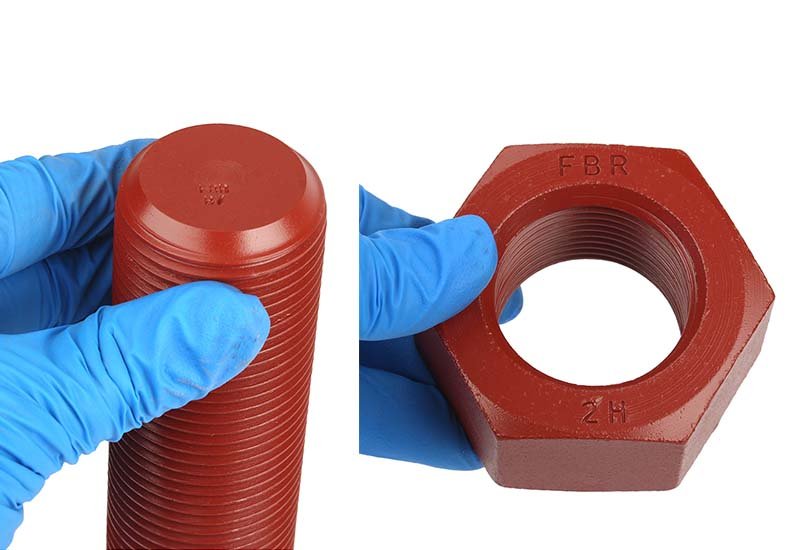

ASTM A193 B7 Stud Bolts with A194 2H Nuts

ASTM A193 B7 Stud Bolts are the workhorse solution for critical pressure piping, refinery equipment,and high-temperature flange joints. When engineers specify stud-bolt assemblies for refineries, petrochemical plants, or power-generation systems, ASTM A193 B7 Stud Bolts combined with ASTM A194 2H heavy hex nuts are often at the top of the list. Made from chromium–molybdenum alloy steel and heat treated for high tensile strength, these stud bolts deliver reliable clamping force in demanding pressure classes and elevated temperature conditions.

In modern projects, designers must consider not only tensile load but also thermal expansion, vibration, gasket relaxation, and external bending. For this reason, ASTM A193 B7 Stud Bolts are engineered to provide consistent torque–tension behavior across a wide temperature range, commonly from −40 °C up to 450 °C depending on code and service fluid. The matching A194 2H nuts are manufactured with compatible mechanical properties so that bolt and nut deform together under load, reducing the risk of joint failure.

As global supply chains evolve, buyers need a partner who understands both technical specification and field conditions. Flybear Fastener supplies fully traceable ASTM A193 B7 Stud Bolts manufactured to ASME B16.5 / B16.47 flange dimensions and inspected to international quality standards, making them suitable for EPC projects and MRO requirements in multiple regions.

Why ASTM A193 B7 Stud Bolts Dominate High-Pressure Flange Connections

The primary reason that ASTM A193 B7 Stud Bolts are specified for so many Class 300–2500 flanges is their combination of high yield strength and predictable ductility. Their alloy steel chemistry delivers higher allowable stress values than plain carbon steel, which means smaller diameters can be used for the same design load. This leads to lighter assemblies and more compact flange designs.

Another advantage is their excellent performance under cyclic loading. Steam lines, hydrocarbon transfer lines, and boiler feedwater systems all experience temperature swings and pressure pulsation. ASTM A193 B7 Stud Bolts maintain preload more effectively than many alternatives, helping the gasket maintain sealing stress and minimizing fugitive emissions.

8UN Thread Series for Critical Pipe Flange Bolting

Many high-pressure flanges call for ASTM A193 B7 Stud Bolts with 8UN thread series. The 8UN thread, defined in ASME B1.1, uses eight threads per inch on a range of diameters and is standard for compact, high-pressure bolting. Compared with UNC series, the 8UN profile has deeper thread engagement and greater shear area, which is especially important for flange stud bolts subjected to high external loads and bending.

In practical terms, the use of 8UN thread bolts improves resistance to thread stripping and enhances the fatigue life of the joint. Technicians in the field also appreciate that 8UN threads are easier to identify and match with corresponding heavy hex nuts, reducing assembly errors during shutdowns and turnarounds.

Benefits of Pairing A194 2H Nuts with B7 Studs

A stud-bolt system is only as strong as its nut. A194 2H nuts are heat-treated carbon steel nuts designed to complement the strength and toughness of ASTM A193 B7 Stud Bolts. Their hardness range, proof load, and chemistry are carefully matched so that both components share similar elastic and plastic behavior. This compatibility ensures even load distribution through the threads and reduces the risk of stress concentration.

For aggressive environments, flange stud bolts are often supplied with additional coatings such as zinc plating, hot-dip galvanizing, PTFE, or Xylan. These coatings, together with appropriate lubricants, improve consistency of the k-factor, allowing torque values to translate more predictably into bolt tension and extending service life in corrosive atmospheres.

Typical Applications for ASTM A193 B7 Stud Bolts

The combination of ASTM A193 B7 Stud Bolts and A194 2H nuts is widely used in:

- ANSI / ASME B16.5 and B16.47 pipe flanges in refineries and petrochemical plants

- Steam lines, boiler outlets, and turbine casings in power-generation facilities

- Heat exchangers, reactors, and pressure vessels in chemical processing

- High-pressure gas compression skids and pipeline block valves

- Offshore platforms, FPSOs, and subsea equipment where high strength is essential

When specified correctly, ASTM A193 B7 Stud Bolts can deliver decades of safe operation. Engineering teams should always confirm design loads, gasket type, flange rating, and service conditions before final selection, but for many high-pressure systems these alloy steel stud bolts remain the first choice.

Follow Me!