Xylan PTFE Coated Stud Bolts and Nuts for Pump & Valve Water Treatment Systems

In modern pump and valve engineering—especially within water-treatment, desalination, wastewater management, and chemical-liquid handling—reliable bolted connections are essential for maintaining system integrity under corrosive and high-pressure environments. Among all available connection solutions, Xylan PTFE coated stud bolts and hex nuts have become a preferred choice for engineers and OEMs who need both mechanical stability and long-term anti-corrosion performance.

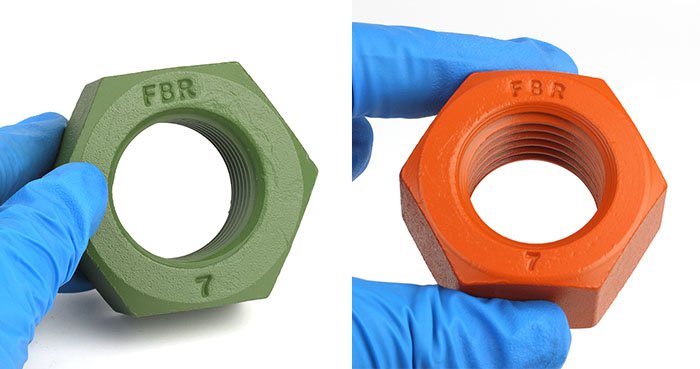

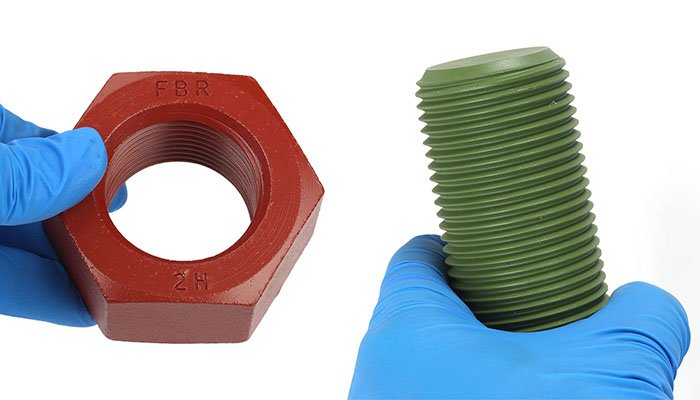

As a specialized global supplier, Flybear Fastener provides a full range of ASME B16.5M, ASTM A193 B7, A320 L7, and A194 2H/Gr.7 Xylan PTFE coated stud bolts and hex nuts widely used in pump and valve assemblies. These components are engineered for the demanding conditions found across water-treatment industries.

Why Xylan PTFE Coating Matters in Pump & Valve Systems

Water treatment environments often involve chemical dosing, chlorinated water, high humidity, and continuous exposure to corrosive elements. Xylan PTFE coating offers several technical advantages:

Superior Corrosion Resistance

Xylan PTFE creates a protective barrier against moisture, wastewater, seawater, chlorine, and aggressive chemicals. This significantly extends the service life of bolted joints in pumps, valves, pipe flanges, and filtration systems.Reduced Friction, Better Torque Control

The low-friction characteristics of PTFE improve tightening uniformity, ensuring more accurate preload, especially in fine-pitch threads used in critical flange assemblies.Anti-Gall & Anti-Seizure Performance

Galling is a major issue in stainless and alloy steel assemblies. Xylan coating prevents thread seizure, enabling easy maintenance and safer disassembly even after long-term exposure.High Temperature & High Pressure Compatibility

For pump and valve manufacturers working with hot water, steam, brine, or chemical media, Xylan coated stud bolts maintain performance across wide temperature ranges.

Applications in the Water-Treatment Industry

Xylan PTFE coated stud bolts and nuts supplied by Flybear Fastener are widely used in:

Clean water pumps and booster pumping systems

Sewage pumps & sludge treatment equipment

Desalination and RO membrane systems

Chlorination/chemical dosing skids

Valve actuators, butterfly valves, gate valves, and check valves

High-pressure pipe flanges (ASME Class 150–600)

Filtration systems and pressure vessels

These coated fastener assemblies ensure mechanical reliability, safe sealing, and reduced risk of bolt-related failures—critical for maintaining uptime in municipal and industrial water-treatment facilities.

Why Water-Treatment OEMs Choose Flybear Fastener

Flybear Fastener supports global manufacturers with:

A full portfolio of Xylan PTFE coated stud bolts A193 B7, A320 L7

A194 2H / GR.7 PTFE-coated hex nuts

Custom fine-pitch threaded studs for precision flanges

Strict testing (salt-spray, adhesion, hardness, coating thickness)

Consistent batch quality and fast lead times

Engineers and procurement teams benefit from long-term reliability and predictable performance—ideal for mission-critical pump and valve systems.

At Flybear Fastener, we continue to uphold the principle of “quality first and customer-oriented,” delivering reliable performance and long-term value to global pump, valve, and water-treatment industries. We are committed to providing high-quality fastener products and comprehensive one-stop industry solutions that support demanding engineering applications.

We welcome customers to explore additional product ranges and technical resources on our website, and we encourage you to contact us for industry-specific guidance, customized recommendations, and competitive quotations.