UNC vs UNF vs UNEF Threads: Differences, Applications, and How to Choose

UNC vs UNF vs UNEF threads is one of the most searched questions when buyers move between inch fasteners and metric systems, or when a bolt “almost fits” but binds after a few turns. These three thread series all belong to the Unified Thread Standard (UTS) family, widely used in the United States, Canada, and many industries that specify inch hardware. While they share the same 60-degree thread form, their thread pitch (threads per inch) differs, which changes strength behavior, stripping resistance, vibration performance, and compatibility with nuts and tapped holes.

This guide explains the differences between UNC, UNF, and UNEF, how to identify them, and how to select the right one for your application. You will also see common search terms like “UNC thread meaning,” “UNF thread pitch chart,” and “UNEF thread applications” addressed in practical, engineering-friendly language.

What do UNC, UNF, and UNEF mean?

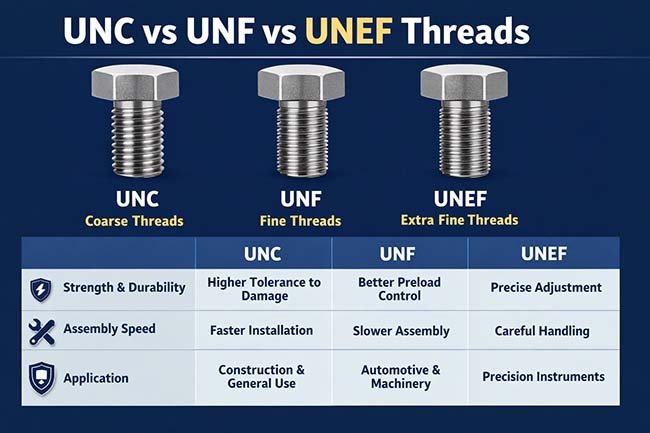

UNC, UNF, and UNEF are Unified thread series defined by different standard pitches for a given nominal diameter:

- UNC (Unified National Coarse): Coarse thread series with fewer threads per inch (TPI). Larger pitch and deeper thread engagement per turn.

- UNF (Unified National Fine): Fine thread series with more TPI. Smaller pitch and more threads engaged along the same length.

- UNEF (Unified National Extra Fine): Extra-fine thread series with even more TPI. Very small pitch, used in specialty applications where fine adjustment or short engagement length is needed.

All are part of UTS and typically use the same basic 60° thread angle form. In purchasing and machining, the biggest practical difference is pitch/TPI, which affects how the fastener behaves under load and in assembly.

How pitch changes performance: coarse vs fine vs extra fine

Thread pitch impacts more than “how many turns it takes.” It influences how the joint resists loosening, how well it holds in softer materials, and how easy it is to assemble in real-world conditions (dirt, paint, damaged threads).

- UNC threads have a larger pitch, which generally makes them more tolerant of plating, dirt, and minor damage. They assemble faster and often work better in softer materials or when frequent installation is expected.

- UNF threads provide finer adjustment and can develop higher clamping force per unit of applied torque in some cases because the helix angle is smaller. They are often preferred in automotive, machinery, and applications where vibration resistance and precise preload control matter.

- UNEF threads are used for very specific needs—thin-wall parts, short thread engagement, or situations requiring precise axial movement per turn. However, they are more sensitive to cross-threading and damage.

UNC vs UNF vs UNEF threads: key differences buyers care about

Below are practical differences that typically matter in engineering drawings, procurement, and field service:

- Compatibility: A UNC bolt will not properly fit a UNF nut of the same diameter, and vice versa. Even if it starts, it will bind and damage threads.

- Assembly speed: UNC usually installs faster due to larger pitch (fewer turns).

- Resistance to stripping in soft materials: Coarse threads (UNC) can be better in softer materials because of deeper thread engagement and larger shear area per thread.

- Vibration and preload stability: Fine threads (UNF) are often chosen for better preload control and can perform well in vibration-prone assemblies when properly designed.

- Damage sensitivity: UNEF is the most sensitive. Small pitch threads are easier to cross-thread and can be harder to repair in the field.

How to identify UNC, UNF, and UNEF on a part

If you’re troubleshooting in maintenance or incoming inspection, these are common steps people use when they search “how to identify UNF vs UNC thread”:

- Check markings and callouts: Drawings might list something like 1/4-20 UNC or 1/4-28 UNF. The number after the dash is TPI.

- Measure the diameter: Use calipers to confirm the nominal major diameter.

- Use a thread pitch gauge: Match the gauge to count threads per inch.

- Compare against a thread pitch chart: Many buyers keep a “UNF thread pitch chart” or “UNC thread chart” for quick verification.

A common mistake is assuming “1/4 inch is 1/4 inch.” The diameter can match while the pitch does not. The result is binding, galling, and damaged nuts or tapped holes.

Where UNC threads are most commonly used

UNC threads are widely used in general-purpose construction, maintenance, and heavy equipment where installation speed and robustness matter. They are also common when components may have less precise alignment or when threads may see debris or coating thickness. Many users searching “coarse thread vs fine thread bolts” choose UNC for field-friendly reliability.

Where UNF threads are most commonly used

UNF threads are common in automotive, aerospace subassemblies (depending on spec), machinery, and applications requiring better adjustment, precise torque-to-tension behavior, or compact joints. They are also frequently specified where a smaller pitch helps maintain preload in dynamic assemblies, assuming correct locking strategy and joint design.

Where UNEF threads are used (extra fine applications)

UNEF is typically used in specialized equipment, instrumentation, thin-wall assemblies, or where fine adjustment per turn is needed. Because extra-fine threads have smaller pitch, they can be advantageous when limited thread engagement length is available, but they require careful handling and clean assembly conditions.

Choosing the right unified thread series for your screws and bolts

When selecting UNC, UNF, or UNEF, match the thread series to your joint requirements rather than habit. Ask these questions:

- Is the assembly environment dirty or field-installed? (UNC is often more forgiving.)

- Do you need precise adjustment and stable preload? (UNF may be better.)

- Is the part thin, with limited engagement length? (UNEF might be appropriate if carefully designed.)

- What mating material are you threading into? (Soft materials often favor coarser threads.)

- Is interchangeability required with existing UTS hardware? (Confirm the exact callout and class.)

Why thread class and fit also matter

In addition to UNC/UNF/UNEF, unified threads are defined by classes of fit (commonly 1A/1B, 2A/2B, 3A/3B). Many buyers also search “2A vs 2B thread” because fit affects ease of assembly, looseness, and tolerance stacking. For most industrial applications, Class 2 is common. Class 3 provides a tighter tolerance and may be used in precision assemblies but can be less forgiving with plating or debris.

How Flybear Fastener supports unified inch thread sourcing

At Flybear Fastener, we help customers source Unified Thread Standard screws, bolts, nuts, and threaded rods with the correct series and fit—UNC, UNF, or UNEF—based on real application needs. If you’re comparing “UNC vs UNF bolts,” verifying a “UNF thread pitch chart,” or trying to prevent cross-threading issues in production, we can support you with clear identification guidance and consistent manufacturing control.

Conclusion

UNC vs UNF vs UNEF threads differ mainly by pitch (threads per inch), which affects assembly speed, tolerance to damage, preload behavior, and use cases. UNC is coarse and forgiving, UNF is finer for precision and stable preload needs, and UNEF is extra fine for specialized applications with limited space or fine adjustment requirements. The safest approach is to confirm the exact callout on drawings, verify TPI during inspection, and ensure all mating components share the same unified thread series and class of fit.