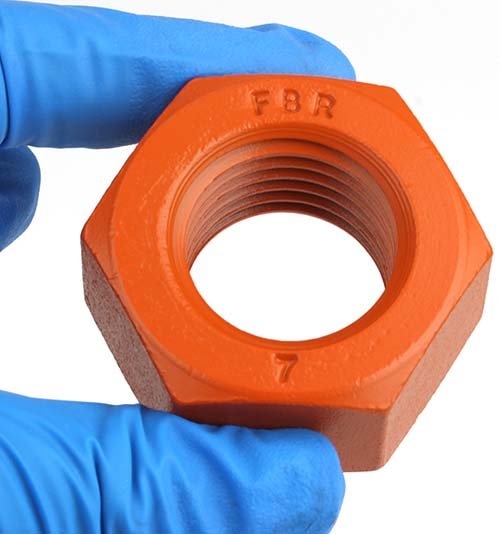

A194 Grade7 Alloy Steel Hex Nuts

Product Overview

A194 Grade7 Alloy Steel Hex Nuts are high-performance fasteners designed for use in high-temperature and high-pressure applications. These hex nuts are primarily used in petrochemical, power generation, and heavy machinery industries where mechanical strength, heat resistance, and durability are critical factors. Manufactured using premium alloy steel and subject to stringent mechanical and chemical specifications, A194 Grade7 hex nuts are engineered for exceptional performance even under harsh conditions.

Flybear Fastener offers a comprehensive range of A194 Grade7 Alloy Steel Hex Nuts, available in various diameters and thread pitches to meet diverse industrial demands. Our commitment to quality and customization makes us a trusted choice for clients across different sectors.

Product Specification Table

| Specification | Details |

|---|---|

| Product Name | A194 Grade7 Alloy Steel Hex Nuts |

| Material | Alloy Steel |

| Nut Type | Hex Nut |

| Grade | Grade 7 |

| Size Range | M6 to M48, 1/4″ to 2″ |

| Thread Type | Metric/UNC/UNF |

| Thread Direction | Right-hand |

| Finish | Plain / Zinc / Hot-Dip Galvanized |

| Standards | ASTM A194, ASME B18.2.2 |

| Packaging | Carton + Pallet or Custom Packaging |

Technical Parameters

| Parameter | Description |

|---|---|

| Strength Class | Grade 7 |

| Surface Treatment | Zinc Plated, Hot Dip Galvanized, Black Oxide, PTFE |

| Certifications & Standards | ASTM A194, ISO 898-2, RoHS, CE |

| Heat Resistance | Operates effectively up to approx. 500°C |

| Hardness | 24 to 32 HRC |

| Temperature Range | -40°C to +500°C |

| Tensile Strength | > 800 MPa |

Materials and Manufacturing Process

The A194 Grade7 Alloy Steel Hex Nuts are made from high-grade alloy steel known for its strength-to-weight ratio and excellent mechanical properties. This grade of steel is particularly suited for applications requiring high tensile strength and good fatigue resistance.

The typical production process includes:

- Raw Material Selection (Alloy Steel Bars)

- Forming: Cold Forming or Hot Forging

- Heat Treatment: Quenching + Tempering to achieve mechanical properties

- Surface Treatment: Zinc Plating / Black Oxide / Galvanization

- Thread Cutting or Rolling

- Final Inspection and Sorting

- Packaging & Labeling

These precise methodologies ensure the consistency, reliability, and optimum performance of each nut delivered by Flybear Fastener.

Common Applications and Industry Use

The A194 Grade7 Alloy Steel Hex Nuts are commonly utilized in:

- Oil and Gas Piping Systems

- High-Pressure Vessels and Boilers

- Heat Exchangers and Reactors

- Power Plants

- Shipbuilding and Offshore Structures

- Heavy Engineering Equipment

- Mining and Construction Machinery

Their strength and endurance make them ideal for critical assemblies exposed to challenging operational environments.

Advantages and Competitive Edge

Flybear Fastener emphasizes quality and performance in every product. Key advantages include:

- Premium Material Quality: Use of certified high-strength alloy steel

- Precision Engineering: Tight thread tolerances and dimensional accuracy

- Advanced Coatings: Multiple surface finishes for corrosion protection

- Customized Solutions: Support OEM/ODM projects, custom specs per client drawing

- Inventory Availability: Standard sizes in stock for quick turnaround

- Comprehensive Support: Expert technical consultation and post-sales service

These capabilities ensure cost-effectiveness and reliability, helping clients reduce maintenance and enhance safety.

Inspection and Quality Control

To maintain top-tier product excellence, Flybear Fastener implements a rigorous quality control process:

- Dimensional Checks using thread gauges

- Mechanical Strength Testing (Tensile, Hardness)

- Salt Spray Testing for corrosion resistance

- Optical Sorting Equipment for batch uniformity

- Torque Testing for assembly performance

- Spectroscopic Analysis to verify material composition

- Certification: ISO 9001 & IATF16949

All nuts undergo 100% surface inspection before shipping. Traceability and documentation are maintained for all orders.

Selection and Procurement Guide

Choosing the correct hex nut requires consideration of:

- Operating Environment (temperature, humidity, exposure)

- Required Strength Class and Load Bearing

- Compatibility with bolt grade

- Thread Type & Tolerance

- Certification Needs (RoHS, CE, etc.)

- Coating or Surface Finish preference

Based on these factors, Flybear Fastener experts can help clients choose the right product variant for their application. Orders can be tailored under custom specifications for both small and bulk procurement needs.

Summary and Company Promotion

At Flybear Fastener, we always uphold the philosophy of “Quality First, Customer Centric.” Whether you’re in power generation, petrochemical, or heavy machinery sectors, our high-quality fastener products are designed to meet diverse performance requirements. With a strong emphasis on engineering reliability, prompt service, and flexible manufacturing, we provide optimized solutions for your most challenging fastening applications.

Please feel free to contact us to get technical support, obtain a quotation, or explore tailored fastener options. Trust Flybear Fastener to be your long-term fastening partner.