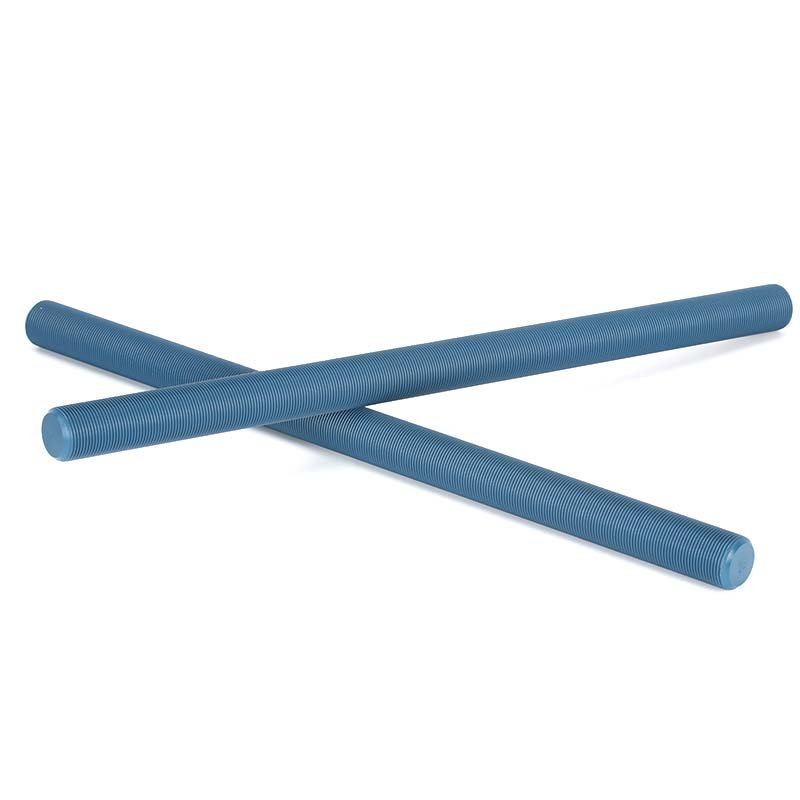

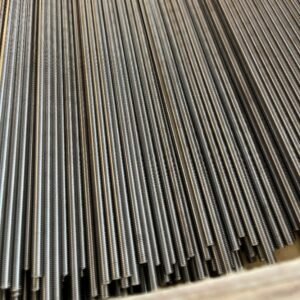

A193 B7 Alloy Steel Thread Rods

A193 B7 Alloy Steel Thread Rods are critical components in a wide range of high-stress industrial applications. These threaded fasteners are manufactured from chromium-molybdenum alloy steel and are heat-treated for enhanced tensile strength. They are specially designed to meet ASTM A193 Grade B7 standards, which are typically used in high-temperature and high-pressure conditions. Whether in petrochemical plants, construction, or power generation, these rods offer exceptional reliability and durability.

Manufactured with precision, these rods are widely used due to their high mechanical properties and corrosion resistance when paired with appropriate coatings. Flybear Fastener offers these products in a variety of dimensions and custom specifications to meet global industrial standards. Learn why A193 B7 Alloy Steel Thread Rods are your go-to option for demanding mechanical fastening applications.

Product Specifications

| Property | Specification |

|---|---|

| Material | ASTM A193 Grade B7 (Type 304) |

| Thread Type | UNC, UNF, Metric |

| Thread Direction | Right-Hand / Left-Hand (customizable) |

| Length Range | 50mm to 3000mm |

| Diameter Range | M6 to M72 / 1/4” to 3” |

| Tolerance | As per ASTM / ISO standards |

| Coatings Available | Zinc, Black Oxide, HDG, PTFE |

| Packaging | Carton + Pallet or Custom Packaging |

Technical Parameters of A193 B7 Alloy Steel Thread Rods

| Parameter | Details |

|---|---|

| Strength Grade | Grade B7 (120ksi min tensile) |

| Yield Strength | Min. 105ksi |

| Surface Treatments | Zinc Plating, Dacromet, Black Oxide, Nickel Plating |

| Standards Compliance | ASTM A193, ANSI B18.31.3, ISO 898, GB/T, RoHS, CE |

| Hardness Range | 28 – 35 HRC |

| Operating Temperature | Up to 450°C |

| Certification | Material Test Reports, COA, ISO9001 |

Material Details and Manufacturing Process

The core material of A193 B7 Alloy Steel Thread Rods is alloy steel, particularly 4140 or 42CrMo materials. These are chosen for their combination of strength, toughness, and resistance to high temperatures. Here’s a quick look at the manufacturing process:

- Raw Material Selection: High-quality alloy bars are sourced.

- Forming: Cold heading or hot forging to shape rods.

- Threading: Precision threading via rolling or cutting.

- Heat Treatment: Quenching and tempering to achieve B7 mechanical properties.

- Surface Finishing: Plating or coating for corrosion protection.

- Inspection: Quality check for dimensions, strength, and surface finish.

- Packaging: Customized packaging for secure transit.

The result is a high-performance thread rod suitable for severe working conditions, guaranteeing durability and load-bearing capacity.

Common Applications Across Industries

A193 B7 Alloy Steel Thread Rods are widely used in:

- Oil & Gas: Pressure vessels, flanges, and valve assemblies.

- Chemical Processing: High-temperature reactors and pumps.

- Power Generation: Turbine housing, insulation fastening.

- Construction: Structural steel buildings, bridges.

- Automotive: High-strength engine and chassis parts.

- Marine: Offshore platforms and installations.

These rods are integral to any environment where maximum strength and temperature resistance are necessary.

Key Features and Competitive Advantages of A193 B7 Alloy Steel Thread Rods

High Strength & Durability

These rods deliver excellent tensile and yield strength, making them ideal for high-load applications.

Corrosion Resistant Coatings

With multiple surface treatment options like Dacromet, PTFE, and Hot-Dip Galvanization, the rods are protected against rust in harsh environments.

Customization

Flybear Fastener offers full customization services including thread type, length, diameter, and coating to suit client requirements and project specifications.

Quality Raw Materials

We only use certified alloy steel (mainly 4140, 42CrMo), ensuring each rod meets or exceeds ASTM standards.

Inventory and Delivery

With a robust inventory system, lead times are minimized, and our logistics partners guarantee timely deliveries worldwide.

Inspection and Quality Assurance

At Flybear Fastener, all A193 B7 Alloy Steel Thread Rods go through stringent quality control procedures:

- Thread Inspection Gauges

- Tensile Testing Machines

- Salt Spray Test Chambers

- Spectrometers for material verification

- Optical Sorting Machines for 100% sorting

- Hardness Testers and Thickness Gauges

- ISO9001, IATF16949 certified quality management systems

Each product is traceable and comes with a detailed material test report (MTR) to ensure compliance and peace of mind.

Thread Rod Selection and Buying Tips

When selecting the correct A193 B7 Alloy Steel Thread Rods, consider the following:

- Environment: Exposure to temperature or corrosive substances.

- Load Requirements: Ensure the strength class meets demands.

- Standards & Certifications: Match to application-specific codes.

- Thread Type: Determine compatibility with mating parts.

- Length and Diameter Compliance: Match geometry with engineering design.

Provide detailed drawings or specifications when placing a custom order to ensure precise fulfillment.

Conclusion

At Flybear Fastener, we pride ourselves on delivering high-performance industrial fasteners. Our commitment to excellence extends from raw material sourcing to post-sales support. We understand the critical importance of fastener products in engineering safety and structural integrity. That’s why we offer not just components, but complete solutions tailored to your industry needs.

Whether you’re sourcing high-strength threaded rods or working on specialized installations, reach out to us for expert advice and customized supply. Feel free to contact us for inquiries, quotes, or engineering support.