Stainless Steel Cage Nuts

Product Overview

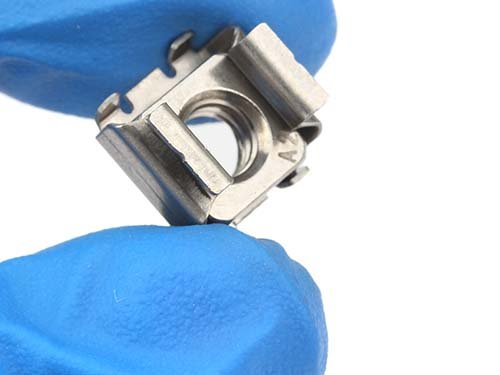

Stainless steel cage nuts are an essential type of fastener used in a wide range of industrial and commercial applications. Also known as captive or square nuts, these components consist of a square nut trapped in a spring steel cage that wraps around it. The cage holds the nut in place and provides flexibility during installation, making them ideal for applications where traditional nuts are not suitable. Their stainless steel construction ensures excellent corrosion and rust resistance, making them suitable for environments exposed to moisture, chemicals, or extreme temperatures.

At Flybear Fastener, we offer stainless steel cage nuts designed to deliver superior performance and durability for any application where high-strength and corrosion resistance are paramount.

Product Specification Table

| Specification | Details |

|---|---|

| Product Name | Stainless Steel Cage Nuts |

| Standard | EN ISO cage-style specs |

| Thread Size | M3-M12 |

| Nut Shape | Square |

| Cage Material | Spring Steel |

| Nut Material | Stainless Steel 304 / 316 |

| Coating Options | Plain |

| Installation Method | Tool-less Snap-In or Clip-On |

Technical Parameter Table

| Parameter | Value |

|---|---|

| Tensile Strength | ≥ 650 N/mm² |

| Corrosion Resistance | > 500 hours (Salt Spray Test, SS316) |

| Thread Tolerance | 6H |

| Operating Temp Range | -50°C to +300°C |

| Surface Roughness | Ra ≤ 1.6 |

| Cage Deflection Angle | Up to 5° Flexibility |

Material Introduction and Production Process

Our stainless steel cage nuts are crafted using premium-grade stainless steel alloys, primarily 304 and 316, known for their superior corrosion resistance and mechanical properties. The spring cage is manufactured from high-tensile spring steel, offering flexibility and ease of installation without compromising strength.

Production Process:

- Precision Material Cutting – raw materials are pre-cut based on desired sizes.

- Nut Forming – using CNC machining or stamping.

- Thread Tapping – ensuring accurate internal threading.

- Cage Formation – stamped and shaped to secure nuts.

- Assembly – Nut inserted and locked within the cage structure.

- Surface Treatment – optional electro-zinc plating for enhanced protection.

- Quality Inspection – conducted at multiple intervals for dimensional and functional accuracy.

Typical Applications Across Industries

Stainless steel cage nuts are commonly used in the following fields:

- Server racks and IT enclosures

- Automotive assemblies

- Aerospace and defense systems

- Industrial machinery

- Telecom cabinets

- Consumer electronics

- Marine equipment

They provide a versatile fastening solution for enabling front-access mounting in racks or enclosures without requiring rear-entry threading.

Advantages and Competitiveness

Flybear Fastener’s stainless steel cage nuts offer multiple key benefits, setting them apart from typical fasteners:

Premium Material Selection

- Constructed using SUS304 or SUS316 stainless steel, providing exceptional resistance to rust, acids, and alkalis.

High Precision Manufacturing

- State-of-the-art CNC and stamping technologies ensure tight tolerances and secure threading with consistent quality.

Advanced Surface Treatments

- Optional zinc plating or black oxide coatings enhance aesthetics and corrosion resistance.

Customization Capability

- We provide OEM & ODM services, ready to manufacture according to customer-provided designs or samples.

Inventory Availability

- Robust warehousing and efficient logistics ensure timely delivery and reduced lead times.

Dedicated After-Sales Support

- Our expert team provides full technical assistance, making procurement and implementation hassle-free.

Company Testing & Quality Control

Flybear Fastener enforces strict quality control protocols throughout our entire manufacturing process. From raw material testing to final performance verification, every batch of cage nuts undergoes:

- Torque & tensile testing

- Salt spray corrosion assessments

- Dimensional checks using calibrated instruments

- Surface roughness and thread gauge inspection

We are ISO 9001 certified, ensuring our quality management system aligns with global standards.

Selection & Purchasing Guidelines

When selecting stainless steel cage nuts, consider these factors:

- Thread Size: Match with screw threads used in your application

- Panel Thickness: Ensure the cage nut is compatible with enclosure panel dimensions

- Material Grade: Choose between SS304 for general use and SS316 for marine or chemical exposure

- Coating: Select coatings based on cosmetic or environmental concerns

- Installation Type: Clip-on or tool-less snap-in options available

To streamline your ordering process, consult our technical team who can provide viability analysis and product customization packs.

Conclusion and Corporate Promotion

Choosing the right fastener products is crucial for the long-term performance and safety of your application. At Flybear Fastener, we manufacture and supply a wide range of stainless steel cage nuts and other fasteners tailored to meet the industry’s diverse demands. We remain committed to excellence, quality, and client satisfaction.

We always uphold the principle of “Quality First, Customer Foremost,” striving to deliver not only high-performance fasteners but also comprehensive solutions tailored to your industry. To explore more products or to obtain tailored quotes, please contact us today.