High‑Strength, Lightweight Titanium Alloy Fasteners

Titanium Alloy Fasteners have emerged as a key enabler in next-generation engineering solutions, offering unmatched performance in demanding environments. In modern industrial manufacturing, fasteners are essential components in mechanical equipment and structural assemblies. Titanium alloy fasteners, known for their lightweight, high strength, and excellent corrosion resistance, have become the preferred choice in high-end industries like aerospace, automotive, marine engineering, and medical devices. As technology evolves, the application scope of titanium alloy fasteners continues to expand, driving industrial manufacturing toward higher efficiency, lighter weight, and greater intelligence. Titanium alloys are thus often called “smart metal,” “space metal,” or “marine metal.”

Advantages of Titanium Alloy Fasteners

1. High Strength with Lightweight Performance

Titanium alloys have only ~60% of the density of steel, yet their tensile strength can exceed 900 MPa—comparable to or even surpassing steel, and more than twice the strength of iron. Their lightweight nature allows significant weight reduction in equipment while meeting high-strength requirements, especially in applications where minimal weight is critical.

2. Excellent Performance at High and Low Temperatures

Titanium alloy fasteners remain mechanically stable across a broad temperature range (−250 °C to +550 °C), with a thermal contraction rate that is only half that of stainless steel. This makes them exceptionally suitable for environments requiring high temperature stability.

3. Superior Corrosion Resistance

Thanks to their natural oxide layer, titanium alloys resist corrosion from seawater, acidic environments, and various chemical media. This makes them more advantageous than stainless steel in highly corrosive settings.

4. Low Magnetic Permeability & Excellent Biocompatibility

Titanium alloys have a magnetic permeability of only ~1.00005, making them ideal for use in precision instruments and electronic equipment where magnetic interference must be minimized. Additionally, they exhibit excellent biocompatibility and do not cause rejection reactions, which is why they are widely used in medical devices.

Common Titanium Alloy Materials and Their Characteristics

- TA2 (Commercially Pure Titanium): Low strength but excellent corrosion resistance and formability. Ideal for chemical or marine equipment.

- TC1 (Ti‑Al‑Mn, α Titanium Alloy): Good formability, weldability, and thermal stability. Common in aerospace engine blades and compressor disks.

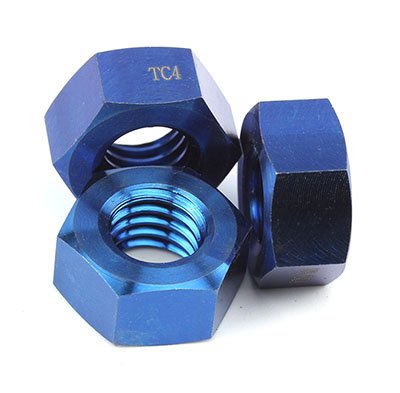

- TC4 (Ti‑6Al‑4V, α+β Titanium Alloy): The most widely used two-phase alloy. Offers balanced performance, ideal for bolts, high‑lock bolts, and rivets.

- TB3 (Ti‑10Mo‑8V‑1Fe‑3.5Al, β Titanium Alloy): After solution treatment, it achieves excellent cold formability and strengths up to 1100 MPa—suitable for high-strength aerospace fasteners.

- TC16 (Ti‑3Al‑5Mo‑4.5V, α+β Titanium Alloy): Enhanced by solution-aging, offers high ductility at room temperature; common in bolts, screws, and self‑locking nuts.

- TC6 (Ti‑6Al‑2Sn‑4Zr‑2Mo, Titanium–Aluminium Alloy): High strength and corrosion resistance at elevated temperatures; often used in aerospace engines and high‑strength structures.

Examples of Titanium Alloy Fasteners

- Hexagon Socket Titanium Screws: Forged for enhanced strength and durability, used in precision instruments and electronics.

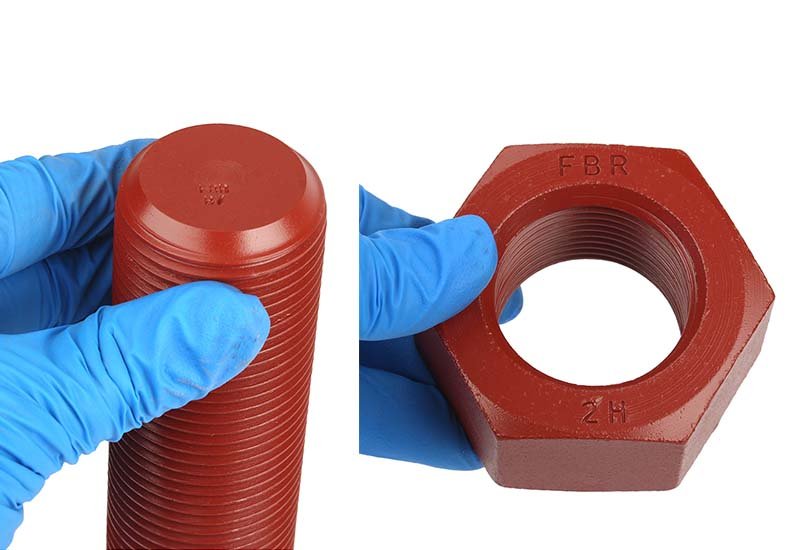

- Hexagon Head Titanium Bolts: High‑strength and corrosion‑resistant, ideal for aerospace and automotive use.

- Titanium Nuts: Lightweight and heat‑resistant, suited for high-temperature and chemical equipment.

- Titanium Flat Washers: Provide even pressure distribution and anti-loosening effects, used in machinery and marine engineering.

Surface Treatments for Titanium Alloy Fasteners

Anodizing (Coloring)

Anodizing produces a titanium oxide layer on the surface, enhancing corrosion resistance and enabling colorful finishes through light reflection.

Nitriding Treatment

Nitriding forms a nitride layer on the surface that significantly increases hardness and wear resistance, suitable for heavy‑load applications.

Coating Enhancement

For specialized applications such as aerospace, additional coatings can further improve corrosion resistance and durability.

Overview of Mechanical Performance Testing Standards

- Tensile Testing: According to ASTM E8/E8M or ISO 6892‑1; measures tensile strength (≥900 MPa), yield strength, and elongation (≥10%) to evaluate load capacity and ductility.

- Hardness Testing: Uses ASTM E384 (Vickers) or Rockwell methods; TC4 typically shows Vickers hardness between HV 320–380.

- Impact Toughness: Conducted per ASTM E23 (Charpy test), often under low-temperature conditions (e.g., −196 °C) to assess brittleness resistance.

- Fatigue & Fracture Toughness: Per ASTM E647/E399; aims for fracture toughness K_IC ≥70 MPa·√m.

- High/Low Temperature Performance: Based on AMS 4928 or GB/T 228; evaluates stability from −250 °C to +550 °C.

- Testing requires calibrated universal testers, hardness testers, and metallographic analysis to verify microstructure (e.g., α+β phase distribution). Industrial-grade alloys (TC4, TA15) must meet AMS 6931 or GB/T 2965 for aerospace and medical-grade compliance.

“Smart Metal” Titanium: The Choice of High-Tech Industries

Thanks to their exceptional properties, titanium alloy fasteners are widely utilized in aerospace, automotive manufacturing, marine engineering, and medical devices. They are the preferred solution for high-tech firms aiming to upgrade product performance.

Advanced Titanium Solutions from Flybear: Beyond Fasteners

Flybear remains committed to pushing the boundaries of metal engineering by delivering tailored titanium solutions that help industries achieve taller, faster, and lighter performance benchmarks across land, sea, air, and beyond.